Chinaware foundation of industrial production

Chinaware foundation of industrial production

Of the rate of shrinkage and the ingredient which are low because the most part of consumption of ceramic raw material is produced by the shape by which the standard was done in quantities as sanitary chinaware, equipment of an insulator and the complementation material of the industrial technology necessary to social life and requests the quality of the world standard of the generality, homogeneity, it’s necessary to give stable production efficiency in quantities by standardization of the raw material synthesis considered in the strength after calcination.

The field earth where it was picked at countryside to know the raw material distribution which satisfies such high-quality standard please, an individual, kaolin, I can think it’ll be help, and a summary of the main raw material is made below.

1. Kaolin

Kaori night was made the main ingredient, plastic, for, the clay which is little but white and has high refractoriness.

2. Potter's clay

Kaori night is made the main ingredient by deterioration granite, the silicic acid part is white relatively much, plastic, rich clay.

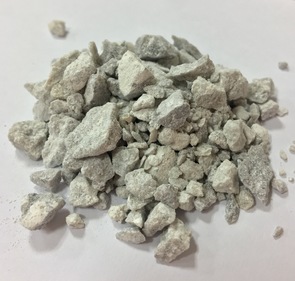

3. Pottery stone

It consists of the feldspar, the quartz and my cirrus mother which become a china raw material by an element raw material, a half, the quartz ridge tuberosity rock which weathered. Formation is possible by a crush particle, plastic, I get it.

4. Silica

I fuse by hotness (1770 ℃-1790 ℃), react with something of a base and deteriorate glassily by thermic effect.

5. Feldspar

Mainly, the structure of the feldspar fuses a silicic acid and alumina glassily by 1200 ℃-1300 ℃ by the one to which sodium, a potassium and calcium were added.

6. Alumina

It’s being used to control glassy fusion by glaze by a high-melting point with a ruby and a sapphire (1800 ℃-2000 ℃) by alumina (oxidation ARUMINIYUMU) and the natural world and make them become stable.

It’s being used to control glassy fusion by glaze and make them become stable by a high-melting point (1800 ℃-2000 ℃).

It’s the reason of which a foundation is composed together with the special quality of the respective raw materials to synthesize kaolin of the purpose, the melting point which is a raw material when I take the case of a raw material of chinaware of general industrial production, and, plastic, using the difference, it’s produced by synthesized kaolin. When I take the case of a raw material of chinaware of the general industrial production, Pottery stone

is added to a kaolin and clay kinds of potter’s clay and a viscosity raw material is made and more alumina of a low viscosity raw material is added during it and it’s made a foundation raw material together with a low viscosity raw material of silica, silica and quartz kinds.

A combination example of composite pottery clay

It can be said the production as which a natural favor was utilized by wisdom will be taken over to tomorrow from today, and that the china etc. a crush was worn, and with which you made Pottery stone of agar has stood up from south Japan. 2 combination examples of typical synthetic kaolin are indicated below.

* Combination example….. clay kinds of pottery (Kifushi clay and potter’s clay), 50%, silica 40% and feldspar 10%.